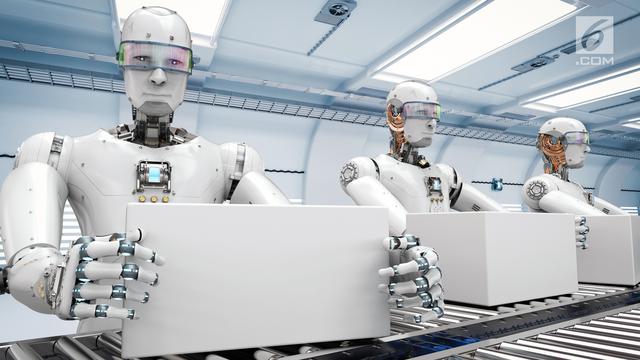

Optimizing Production Efficiency with Robotics – In this era of modern industrial development, it is important for companies to find new ways to increase their production efficiency. One technology that plays an important role in this regard is robotics. Robotics is the science and technology concerned with the design, construction, operation and use of robots in various applications.

Optimizing Production Efficiency with Robotics

By using robotics

companies can optimize their production efficiency in a number of ways. First of all, robots can perform repetitive and repetitive tasks with a high degree of accuracy. This reduces human error and minimizes the time needed to complete the tasks. For example, in the assembly process, robots can pick up and install parts with speed and precision far beyond human capabilities.

Apart from that

robotics also allows companies to automate their production processes. By using well-programmed robots, companies can ensure that production runs smoothly without human hindrance. Robots can work 24 hours a day without getting tired, increasing production output significantly. In addition, robots can also be equipped with sensors that allow them to interact with their environment. This allows them to avoid obstacles, optimize movement routes and avoid potential accidents, thereby increasing production safety and efficiency.

Robotics also allows companies to undertake flexible mass production

Using reprogrammable robots, companies can easily change production configurations to meet changing market demands. For example, if there is high demand for a particular product, a company can quickly reprogram robots to produce that product in large quantities. This allows companies to respond quickly to market changes and maximize business opportunities.

In addition, robotics can also improve job security. In hazardous or high-risk industries, the use of robots can reduce the risk of accidents and injuries that human workers may experience. Robots can take on potentially hazardous tasks, such as lifting heavy loads or working in environments with extreme temperatures. This not only protects the health and safety of workers, but also reduces the costs associated with work injuries and absenteeism.

However, the implementation of robotics in production also has its challenges. First of all, the initial cost of buying and installing a robot can be prohibitive for some companies, especially smaller ones. In addition, there is also a need to train workers in using and interacting with robots. This requires additional time and effort, and some workers may experience discomfort or worry about losing their jobs. Therefore, companies must take steps to ensure that the transition to the use of robotics is well executed and accommodates the needs and concerns of workers.

In conclusion, robotics is an effective tool for optimizing production efficiency in modern industries. By using robots, companies can improve accuracy, automate production processes, optimize flexibility, improve job security, and respond quickly to market changes. However, challenges such as cost and worker training need to be addressed judiciously. By considering the benefits and challenges of robotics, companies can take appropriate steps to make effective use of it, advance their production, and stay competitive in today’s competitive global market.

In this era of modern industrial development, it is important for companies to find new ways to increase their production efficiency. One technology that plays an important role in this regard is robotics. Robotics is the science and technology concerned with the design, construction, operation and use of robots in various applications.

By using robotics, companies can optimize their production efficiency in a number of ways. First of all, robots can perform repetitive and repetitive tasks with a high degree of accuracy. This reduces human error and minimizes the time needed to complete the tasks. For example, in the assembly process, robots can pick up and install parts with speed and precision far beyond human capabilities.

Apart from that, robotics also allows companies to automate their production processes. By using well-programmed robots, companies can ensure that production runs smoothly without human hindrance. Robots can work 24 hours a day without getting tired, increasing production output significantly. In addition, robots can also be equipped with sensors that allow them to interact with their environment. This allows them to avoid obstacles, optimize movement routes and avoid potential accidents, thereby increasing production safety and efficiency.

Robotics also allows companies to undertake flexible mass production. Using reprogrammable robots, companies can easily change production configurations to meet changing market demands. For example, if there is high demand for a particular product, a company can quickly reprogram robots to produce that product in large quantities. This allows companies to respond quickly to market changes and maximize business opportunities.

In addition, robotics can also improve job security. In hazardous or high-risk industries, the use of robots can reduce the risk of accidents and injuries that human workers may experience. Robots can take on potentially hazardous tasks, such as lifting heavy loads or working in environments with extreme temperatures. This not only protects the health and safety of workers, but also reduces the costs associated with work injuries and absenteeism.

However, the implementation of robotics in production also has its challenges. First of all, the initial cost of buying and installing a robot can be prohibitive for some companies, especially smaller ones. In addition, there is also a need to train workers in using and interacting with robots. This requires additional time and effort, and some workers may experience discomfort or worry about losing their jobs. Therefore, companies must take steps to ensure that the transition to the use of robotics is well executed and accommodates the needs and concerns of workers.

In conclusion, robotics is an effective tool for optimizing production efficiency in modern industries. By using robots, companies can improve accuracy, automate production processes, optimize flexibility, improve job security, and respond quickly to market changes. However, challenges such as cost and worker training need to be addressed judiciously. By considering the benefits and challenges of robotics, companies can take appropriate steps to make effective use of it, advance their production, and stay competitive in today’s competitive global market.