How industrial technology is shaping the future – Industrial technology has a very important role in shaping our future. As technology continues to advance, industries around the world are undergoing significant transformations, opening the door for extraordinary innovation and profound changes in various sectors.

What are the impacts

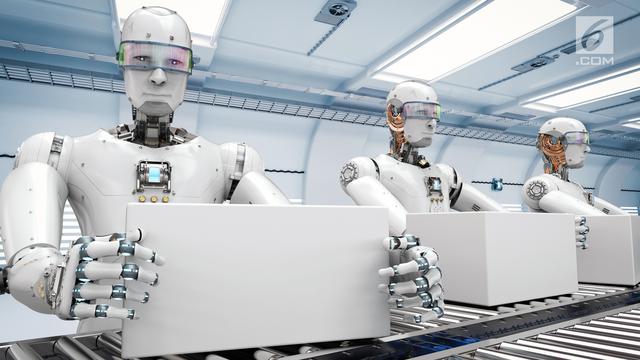

One of the biggest impacts of industrial technology is the creation of higher efficiency in the production process. Developments in automation and robotics have allowed companies to drastically increase their productivity. Factories that used to require a large amount of human labor can now be operated by sophisticated machines that can perform repetitive tasks quickly and accurately. This not only reduces production costs, but also improves product quality and reduces human error rates.

How industrial technology is shaping the future

In addition, industrial technology has also facilitated developments in the field of communication and connectivity. The internet has become the backbone of the digital revolution that is happening. With easy access to information and the ability to connect with people around the world, collaboration between companies and individuals becomes easier. Big projects can be carried out together with teams located in different parts of the world, generating new ideas and better solutions.

How is the development of industrial technology

In addition, industrial technology has also opened the door for the development of renewable and environmentally friendly energy. In facing the problems of climate change, global warming, and dependence on fossil energy resources, the industry needs to find sustainable solutions. Industrial technology has resulted in significant advances in the development of renewable energy such as solar energy, wind energy and hydro energy. In addition, innovations in energy storage and energy efficiency have also helped reduce the industry’s negative impact on the environment. How industrial technology is shaping the future,

Apart from the energy sector, industrial technology has also shaped the future of transportation. Electric and autonomous vehicles are a fast growing trend. With better battery technology and more affordable production costs, electric cars are becoming a more attractive option for consumers. In addition, the development of autonomous technology allows cars to drive themselves using sophisticated navigation and sensor systems. This can increase efficiency, safety, and reduce congestion on the highway.

Apart from these effects

Industrial technology also contributes to the fields of health and medicine. Developments in pharmaceuticals, medical devices, and information technology have enabled more accurate diagnoses, better treatments, and the discovery of new drugs. Technologies such as medical imaging, surgical robotics and telemedicine have changed the way we interact with the healthcare system. In the future, we may see new discoveries that will resolve diseases that are currently difficult to cure.

However, industrial technology also faces challenges that need to be overcome in creating a better future. One of the main challenges is ensuring that technological developments do not create greater social inequalities. The digital divide can occur when only a portion of society has access to and use of technology, while others are left behind. It is therefore important for governments, companies and communities to work together to ensure equitable access to technology and develop the skills necessary to use it.

In conclusion, industrial technology has a very important role in shaping our future. With higher efficiency, better connectivity, development of renewable energy, more intelligent transportation, better healthcare and challenges that need to be overcome, industrial technology has great potential to create a better world. However, it is important for us to face this challenge wisely and ensure that technology is used for the greater good and for the common good.